October 15-17, 2024, “China (International) Automotive Lightweight Casting Technology Summit Forum and China Foundry Association Automotive Casting Branch 2024 Annual Meeting” was held in Xiangyang City, Hubei Province. As the most influential industry event in the automotive casting industry, it brought together many industry elites and business representatives. The meeting was co-organized by China Foundry Association Automotive Casting Branch, Automotive Brake Casting Branch, Ferroalloy Branch, Volunteer Working Committee, Jilin Foundry Association, and ZhongAng New Material actively participated in the meeting!

This meeting to “the development of the automotive casting industry” as the theme, to explore the solution to the automotive field in the context of the new era of China's new energy vehicles development road. New energy vehicles as an important trend in the future automotive industry, the manufacture of its key components can not be separated from the strong support of the casting industry. These parts are not only required to have high strength, high toughness, high corrosion resistance, but also need to meet the design requirements of lightweight, precision and integration to enhance the performance, safety and range of new energy vehicles.

In the casting process, through accurate control of casting parameters, optimization of casting process, selection of high-performance casting materials, can be manufactured to meet the requirements of new energy vehicles precision parts. For example, the use of high-pressure casting technology can produce a uniform wall thickness, compact structure of the motor shell; the use of sand casting or investment casting process, you can produce a complex shape, high precision cylinder block, cylinder head and other engine parts, gears, bushings and other transmission components, control valve body and so on.

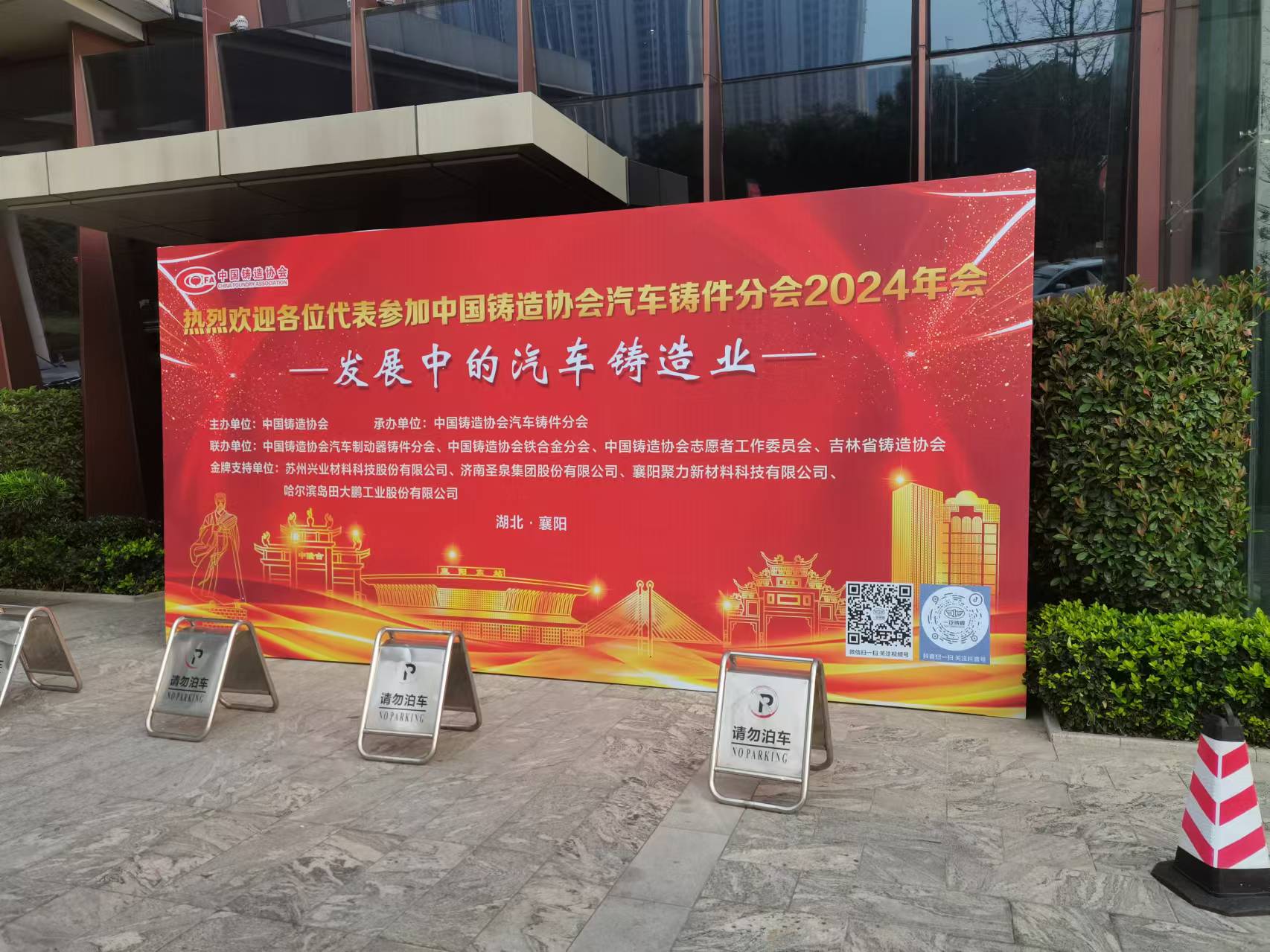

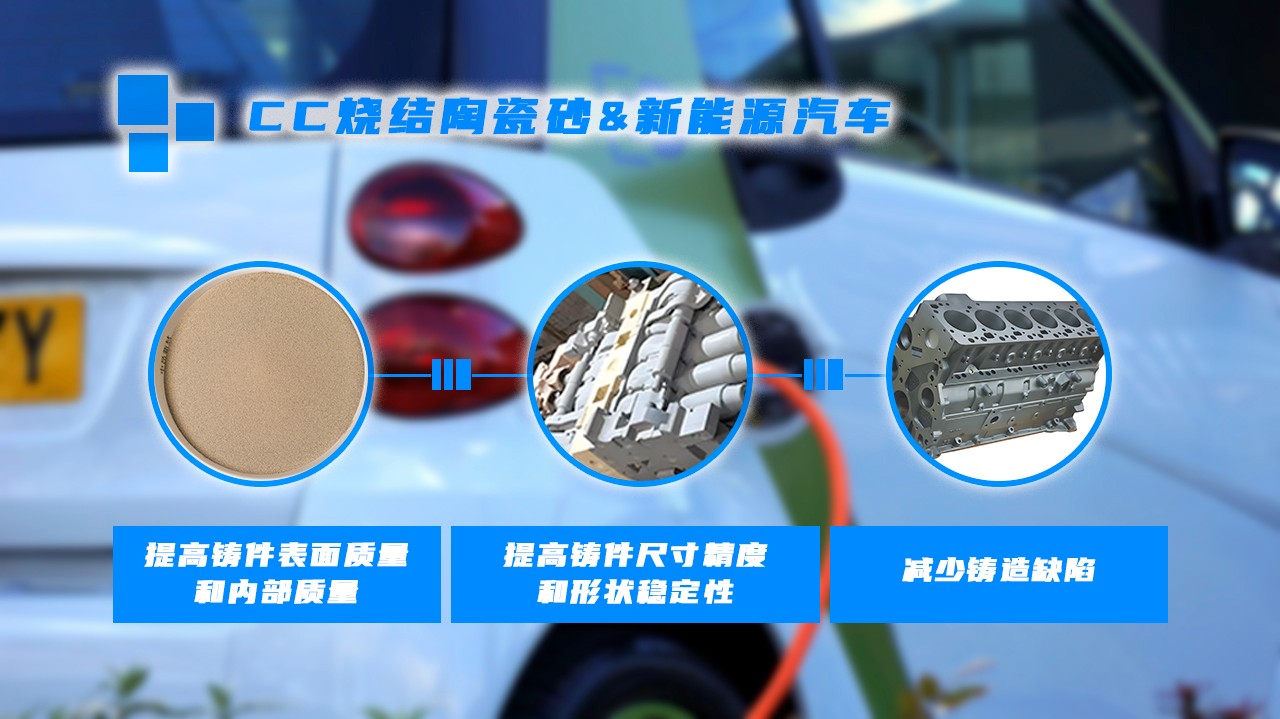

CC sintered ceramic sand independently developed byZhongAng New Material is an environmentally friendly refractory material specially applied to sand casting and investment casting process, which has the performance characteristics of high refractoriness, good sphericity, low expansion rate, low bulk density, low resin addition, low outgassing, low fragmentation, good fluidity, good collapsibility and so on. Using CC sintered ceramic sand for casting can significantly improve the surface quality and internal quality of castings, improve the dimensional accuracy and shape stability of castings, and reduce casting defects.

In short, the rapid development of the new energy automobile industry, casting technology plays an important and indispensable role in its industrial chain, providing strong support and guarantee for the sustainable development of the new energy automobile industry. As a technology company specializing in the research, development and production of casting refractory materials,ZhongAng New Material will pay close attention to the dynamics and needs of the new energy automobile industry, continue to increase investment in research and development, and continuously improve the performance and quality of the products to help the development of new energy automobile industry!