In recent years, 3D printing technology has developed rapidly and has been applied on a large scale in the field of casting because of its advantages of simplifying the casting process, shortening the manufacturing cycle and improving the quality of castings. At the same time, it has promoted the rapid development of its material foundry sand industry.

In the past, China's foundry 3D printing sand is mainly silica sand, but with the increasing quality requirements of castings, the production of environmental protection gradually strict at the moment, the shortcomings of silica sand is becoming increasingly apparent, not only in the use of the process is easy to break, the production of high precision castings there are also serious problems of sticky sand, affecting the overall quality of castings. And China Casting Sand as a green and environmentally friendly casting materials, with high refractoriness, low thermal expansion rate, high recovery rate, is considered to be the ideal material to replace the casting silica sand.

Development and application of China Casting Sand 3D printing process

Test preparation

Binder: special furan resin and sulfonic acid curing agent for 3D printer

Equipment: casting 3D printer, sand strength machine, tank ball mill, oscillating sand sifter

Test process

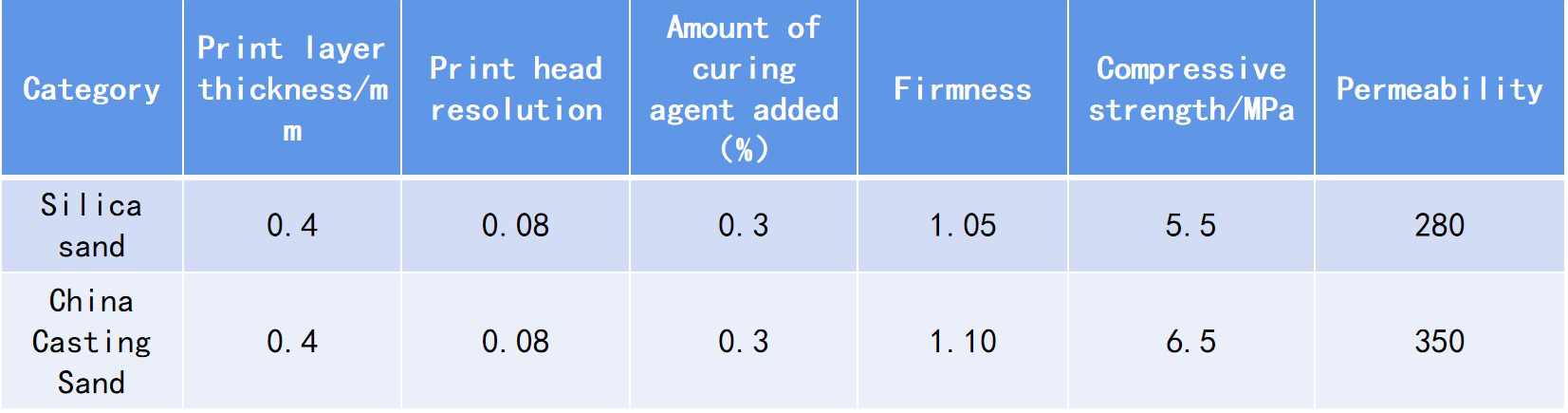

1. printing compressive test blocks of size 40mm×40mm with silica sand and China Casting Sand respectively, measuring the strength and mass of the test blocks with an intelligent sand strength machine and an electronic balance, and taking the ratio of the density of the test blocks to the density of the sand pile as the compactness of the sand core.

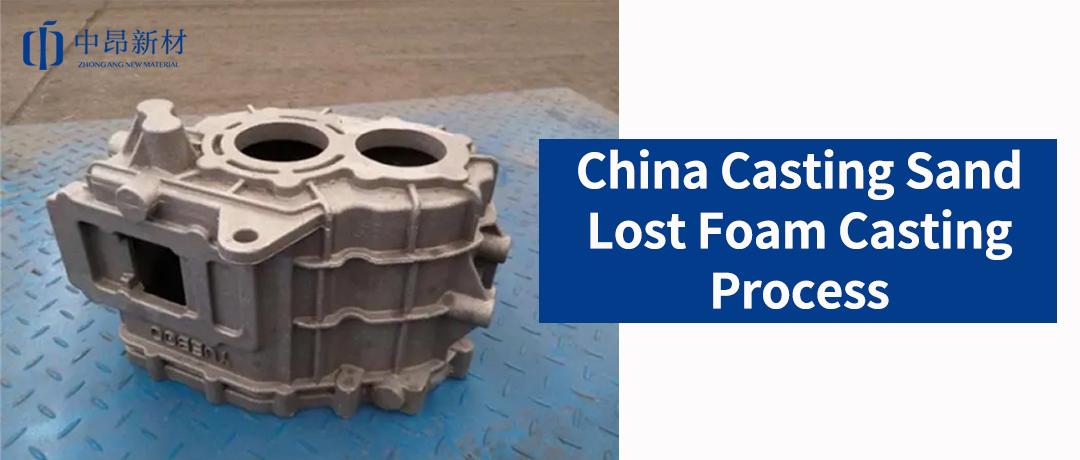

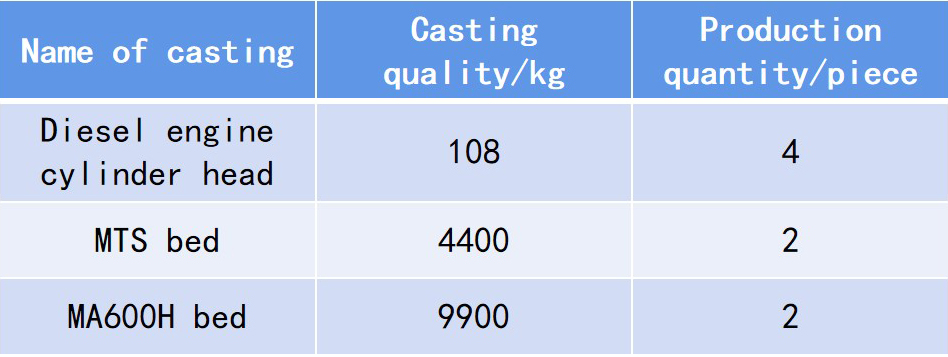

2. printing diesel engine cylinder head, MTS bed, MA600H bed casting sand type (core) with casting 3D printer with surface flow coating thickness of 0.5mm.

Table 1 - Casting name and quality

3. 500g of sand were sampled from the castings after sand cleaning, with 100g as 1 sample, and the sand was mechanically ground with a 20mm diameter steel ball and a jar ball mill at 300r/min for 1h to simulate the mechanical regeneration process, and the particle size distribution of the regenerated sand was detected with an oscillating sand sifter, and the regeneration rate of the sand was calculated with the residual mass of 50 mesh + 70 mesh + 100 mesh sand.

Test results

Table 2 - Printing parameters and results

From the data: the compressive strength of China Casting Sand cores printed with the same parameters of 3D printer is 18% higher than that of silica sand cores, and the compactness is also higher than that of silica sand.

The diesel engine cylinder head castings cast with China Casting Sand cores are free of sticky sand and vein defects, and the pass rate is higher than that of silica sand castings.

For larger machine tool castings, the castings produced by silica sand sand mold (core) have chemical sticky sand, which is difficult to clean up later, and the castings have more vein defects; while the castings produced by China Casting Sand mold (core) have mechanical sticky sand, but it is easier to clean up, and because of the low expansion coefficient, the inner cavity of the casting is not easy to produce vein defects.

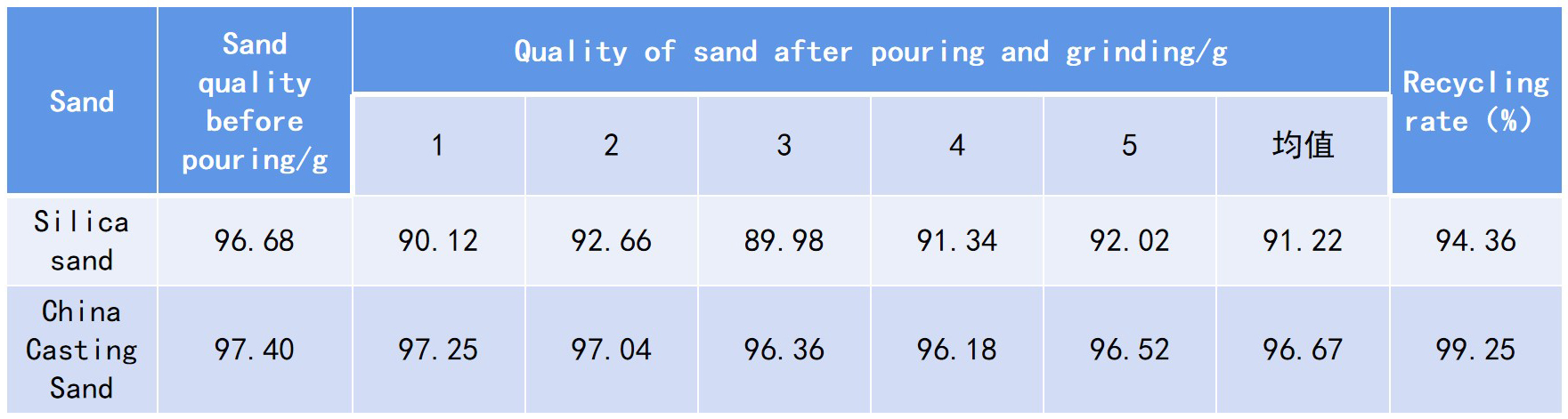

Table 3 - Sand regeneration rate experimental results

From the data: the regeneration rate of China Casting Sand is 99.25%, and the regeneration rate of silica sand is 94.36%, mainly due to the round shape and small angular coefficient of China Casting Sand, which is not easy to break in the grinding process, so the regeneration utilization rate has obvious advantages.

(The above experimental data were provided by KOCEL. Article number: 1003-8345 (2019) 04-0046-03; the company selected China Casting Sand for 3D printing casting.)

Summary

The combination of 3D printing technology and traditional casting process helps to promote the transformation and upgrading of casting enterprises, and ZhongAng New Material will continue to innovate and continuously optimize and upgrade our products to help the development of 3D printing technology for domestic casting sand and provide high-quality foundry sand for our customers!